Tutorials

Sculpted Relief Resin Mold within an Open Bezel

Learn this technique from this tutorial below!

Be Inspired!

Learn How!

Materials Needed:

- Nunn Design Open Frame Bezels

- Easy Mold Silicone Putty

- Brass Metal Stamping

- Nunn Design 2-Part Resin Kit

- Castin’ Craft Opaque Pigments

- PearlEx Mica Powder

Other:

- Q-tip

- Wetwipes

- Toothpicks

- Business Cards

Make the Silicone Mold

Step 1:

Select a Nunn Design Brass Stamping or a found object such as the fossil I am using in this tutorial. Brass Stampings or found objects with a lot of relief make the best sculpted relief molds.

Step 2:

Pinch off two equal sized balls of Part A and B of the Easy Mold Silicone Putty. Getting the knack for mixing just the right amount of putty will take some practice. You might mix too much or too little putty the first time. Try your best to guess how much putty you will need to have approximately 1/8” putty around the outside edge of your bezel’s rim. You will also want the thickness of the silicone putty to be approximately ¼”.

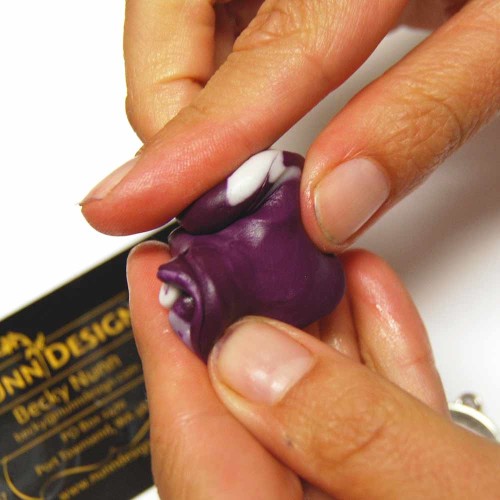

Step 3:

The Easy Mold Silicone Putty has a 3-minute working time before it begins to harden and not take the impression. Knead both part A and part B together until the putty is blended completely and has a uniform color.

Step 4:

Roll the fully mixed Easy Mold Silicone Putty into a round ball and flatten slightly. Make sure the putty is smooth and not wrinkled. Press your brass stamping or found object into the silicone putty, but not so far into the putty that you hit the bottom.

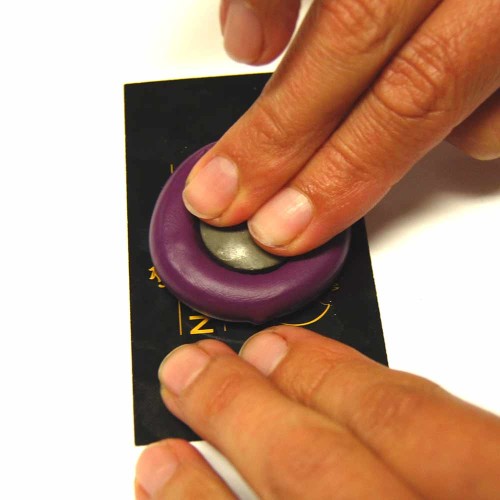

Step 5:

Quickly remove the brass stamping or found object and press in your Open Back Bezel in a position that frames the brass stamping impression. Be sure to double check that your bezel is level in the mold. Let the Easy Mold Silicone Putty set for 25 minutes. Tip: To prevent your mold from sticking onto your work surface, use a glossy business card or a Ziploc bag.

Mixing and Colorizing the Nunn Design 2-Part Resin

Step 6:

Read the resin instructions for safety concerns regarding the Nunn Design Resin.

When I work with resin, I always:

- Place a large plastic bag over my work surface and tape it down.

- I make sure I have ventilation in my workroom.

- I wear gloves.

- I wear glasses (readers because I can’t see anymore. Plus it protects my eyes!).

- I have a pile of wet wipes handy.

- This is a great blog post that covers 20 Habits for Successfully Using Nunn Design 2-Part Epoxy Resin. Even if you are a seasoned resin mixer, this might be worth a read.

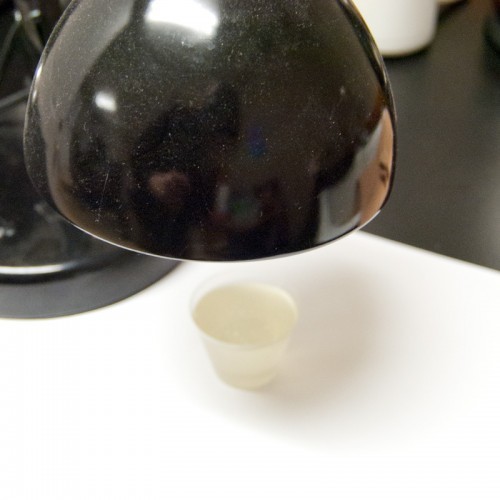

Step 7:

Place one cup (included in the Nunn Design Resin Kit) onto your table. For curing purposes, it is very important that the resin be an exact 1 to 1 ratio of Part A and Part B. I suggest getting your eyes level with the resin so you can see the lines on the measuring cup. Pour Part A of your resin kit up to the ½ fluid ounce mark on your measuring cup.

Pour Part B of your resin kit into the same cup until it is filled to the 1 fluid ounce mark.

Step 8:

Set your timer for 2 minutes. Using the stir stick from your kit (a popsicle stick or coffee stir stick will work great too), slowly and carefully stir your resin scraping the sides as you stir. Stir for a minimum of 2 minutes. If your resin is still cloudy continue to mix until clear. After mixing is complete and your resin is clear, scrape both sides of your stir stick on the edge of your resin filled cup.

Set the mixture under a warm lamp for 5 minutes. This aids the air bubbles in the resin to rise to the surface and pop.

Step 9:

After your resin has been under the lamp for 5 minutes, pour a small amount of the mixed resin into a second measuring cup. Add in a toothpick tip worth of the Castin’ Craft Opaque Pigment Yellow and Castin’ Craft Opaque Pigment Blue to create the teal color show here. You can mix the full 1 fluid ounce measuring cup of resin if you want, but I transfer the resin into smaller cups because it is easier to stir and less messy to move around when less full. Tip: Be sure that the colorant does not equal more than 10% of your resin as having more than 10% could cause issues with curing!

Pour Mixed Resin into the Silicone Mold

Step 10:

Using a Q-Tip, rub some PearlEx Mica Powder into the crevices of the silicone mold. Place back into the mold the Open Back Bezel before pouring in the colorized resin. Using your stir stick, drizzle the colorized resin into the bezel. Before the bezel is filled to the flush level of the bezel, take a toothpick and gently move around the resin to see if there are any air bubbles trapped in your mold or along the edge of the bezel. If any air bubbles are within the resin, they will rise to the surface from the agitation. Move the bubbles to the edges to pop, or breathe on them. The hot air from your breath will make the air expand and the bubble will pop.

Step 11:

Let your resin cure for 24 hours. Once cured, slightly bend back the edges of the silicone mold to release the resin and bezel.

Important Information! This technique is ideal for the Nunn Design Open Bezel Deep Channels and the Open Frame Pendants in our product line. Because these bezel pieces are machined from brass and then plated, there are no irregular edges. Cast bezels do work, but the resin can seep out from underneath the rim of the bezel while it is in the mold. This causes additional clean up, but does look great!

Watch the Video!

Isn’t this just the bomb! No clean up! No sanding! Just BOOM!

Design Option:

Here is an example of the same technique, but the item was pressed into the molding putty on step 4 was not recessed, it was raised. The impression was created with a vintage button and provided a great relief to the sculpted resin. The Nunn Design Resin was also not colorized nor was PearlEx Powders rubbed into the silicone mold. It was all 100% natural.

Shop Nunn Design Wholesale

Nunn Design has been supplying jewelry artists with findings for over 20 years. Shop wholesale jewelry findings for creative jewelry makers.

Shop Nunn Design!How to Purchase Wholesale?

If you are interested in becoming one of the many designers who trust their jewelry to Nunn Design Findings, please join us by registering to become one of our wholesale customers!

Please visit our Where to Buy Page for a listing of online stores that sell Nunn Design Findings retail.

If you enjoyed reading this post, please subscribe to our blog. Here are 10 Reasons Why to Subscribe and a place to do so!

Ok Becky – you have come up with some cool ideas before. I mean some VERY cool ideas. However, this idea? THIS IDEA is ahhhhh-MAZING!! This is my very favorite. I am now obsessed. Can you please just come to my office, bring a slew of Open Bezel Deep Channels with you, and we’ll just play until we can’t see straight?!

I nominate Becky Nunn for a Nobel Prize in Crafting.

I’m glad this Buy & Try doesn’t begin until day after tomorrow. Although I have the stuff to make these, I need more…and I’ll need time to apply for a second mortgage to buy enough Open Back Deep Channels to experiment with all the ideas this gives me! I LOVE THIS – thank you so very much for this, you creative goddess!!

Wow! What an amazing response! Thanks so much Katherine for your kind words and encouragement. My staff got a good chuckle about the “creative goddess” part!

Terrific tutorial Becky! Thank you for sharing your tips and tricks. I love that pyritized ammonite you used to make the mold.

Thank you Jill. I love it too!

I would like to get on your mailing list for jewelry making ideas. Thanks…Nancy