These Hammered Bitsy Rings with Epoxy Clay are super fun and super fast to create! And take a look at how they stack together! Yes please!!!

Super lightweight gilding flakes are available in three metallic colors, bronze, gold and silver. They are perfect for working with Epoxy Clay! Slightly wet the tip of a toothpick and pick-up the gilding flakes. Tack the gilding flakes onto the Epoxy Clay by gently touching the flakes to the clays wet surface. Gently rub the gilding flakes into the clay with your fingertips.

Test the gilding flakes out and explore them with this technique prior to purchasing a larger container directly from Tonic Studio.

This is 4 of 6 tutorials featured in our Nunn Design blog featuring Earring Post Bars in Large and Small as well as our Hammered Bitsy Rings.

Supplies:

To manufacture these little cuties, a brass bezel is soldered, with lead-free solder, onto a brass ring shank. We then plated the rings with 24k gold and .999 fine silver. A final touch of oxidization is applied to provide an aged look to the precious metal.

Supplies Needed:

- Nunn Design Hammered Bitsy Rings

- Epoxy Clay-Black

- Gilding Flakes

Other Supplies:

- Rubbing Alcohol

- Q-Tips

- Wet-wipes

- Toothpicks

- Business Cards or glossy card stock

Learn How:

Step 1:

The Nunn Design Findings are oxidized to provide the antique look to the precious metal plating. The oxidization, when it comes into contact with the Epoxy Clay could change the color of the clay. To avoid this, clean the findings thoroughly prior to applying the clay. Get the tip of a Q-Tip wet with rubbing alcohol and clean away any of the blackened oxidization on both sizes of the Hammered Bitsy Rings.

Step 2:

Follow the manufacturer’s instructions for the handling and mixing of the black Epoxy Clay. Epoxy Clay is epoxy clay that air-dries. It sets in 2 hours and continues to cure 14-16 hours. There is no baking required, no shrinkage.

Step 3:

While wearing gloves, pinch off two equal sized balls of Part A and Part B and blend together fully until the clay is no longer marbled and uniform in color. You have approximately 90-120 minutes of working time before the clay starts to harden, so take your time. Once the clay is thoroughly mixed, remove your gloves to make it easier to work with the clay. For this tutorial, I mixed a small lentil sized ball of both Part A and B of clay.

TIP: If the Epoxy Clay is really sticking, let it sit for 15 minutes. This will allow the fresh clay to have time to set-up a little bit, resulting in it not being as sticky to manage.

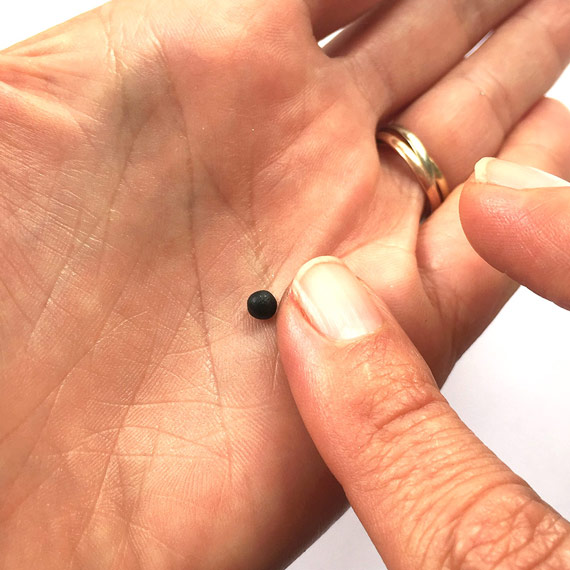

Step 4:

Pinch off a very small ball of clay and roll it into a smooth ball using the palm of your hand and fingers. It will take time to get just the right amount of clay that you will need insert into the Hammered Bitsy Ring bezel, so be patient if you have to remove excess clay or add more the first time you do this.

Step 5:

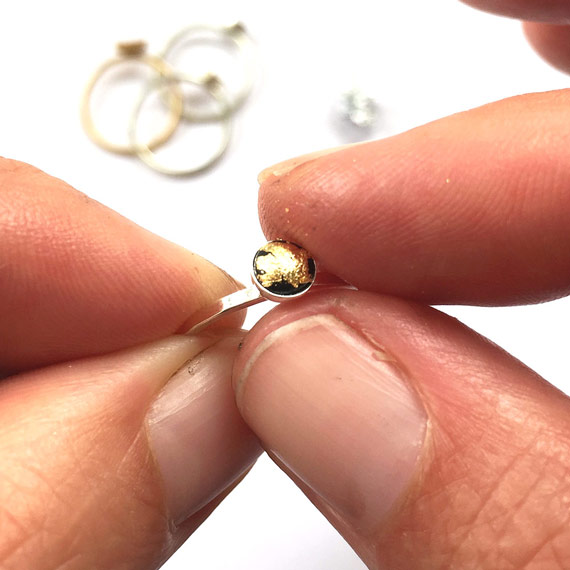

Press the small smooth round ball of clay into the ring bezel with your fingertips. On the Hammered Bitsy Drop and Triangle Rings, use a toothpick to push the Epoxy Clay into the corners of the bezel.

Step 6:

Wipe your hands thoroughly with a wet-wipe. Wipe away any excess Epoxy Clay from the ring bezel (if any is on it). The Epoxy Clay will harden like cement, so it is best to make sure that any area that you don’t want clay is clean.

Step 7:

If you have finger prints in your clay, or if you want the surface to be smoother than you have it, wet your fingers slightly with water and rub the Epoxy Clay. The water will help smooth the clay.

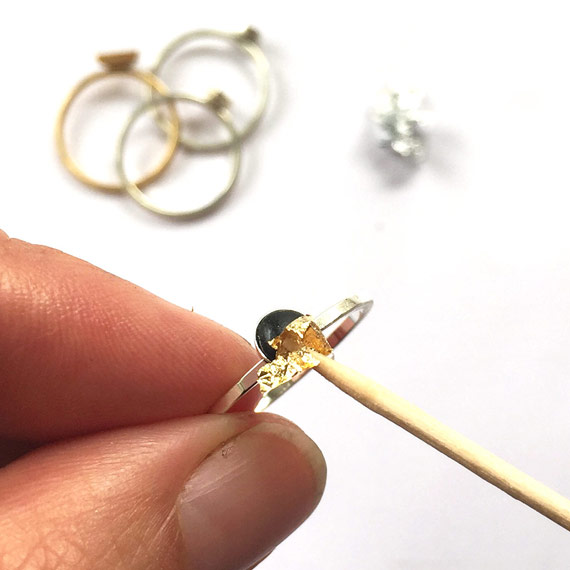

Step 8:

Place some Gilding Flake onto your work surface. Wet the end of a toothpick and gently touch the Gilding Flake to pick it up. Place the flake onto the wet Epoxy Clay and slightly tack into place.

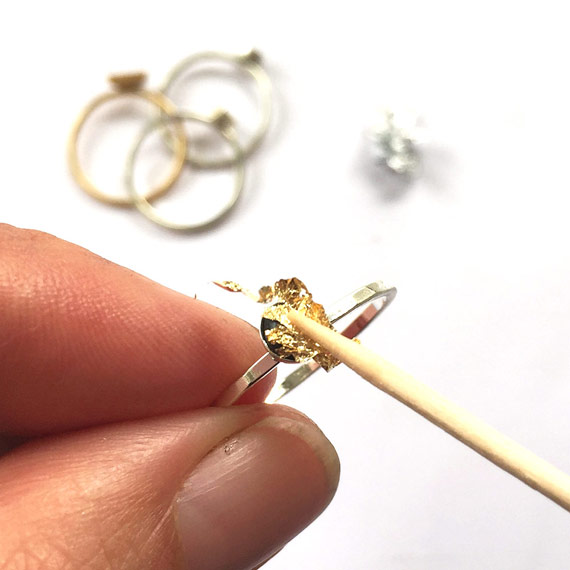

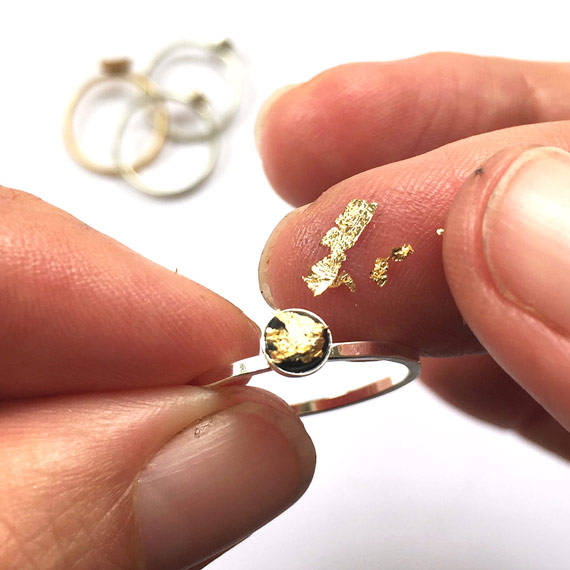

Step 9:

Once the Gilding Flake is released from the toothpick, start to rub the flake into the Epoxy Clay with your fingertips. The Gilding Flakes tear very easily, but don’t worry. Just continue to adhere it onto the clay until you have your desired effect. Gently rub the Gilding Flakes into the Epoxy Clay until it is smooth.

Step 10:

Let the pieces cure. They will set up in 2 hours and will continue to cure for 14-16 hours.

Design Option:

To have a high gloss finish, mix-up a batch of Nunn Design 2-Part Resin and drizzle it onto the surface of the Epoxy Clay. Although this is a nice effect, it isn’t required to protect the gilding flakes.

Shop Nunn Design Wholesale

Nunn Design has been supplying jewelry artists with findings for over 20 years. Shop wholesale jewelry findings for creative jewelry makers.

Shop Nunn Design!How to Purchase Wholesale?

If you are interested in becoming one of the many designers who trust their jewelry to Nunn Design Findings, please join us by registering to become one of our wholesale customers!

Please visit our Where to Buy Page for a listing of online stores that sell Nunn Design Findings retail.

If you enjoyed reading this post, please subscribe to our blog. Here are 10 Reasons Why to Subscribe and a place to do so!